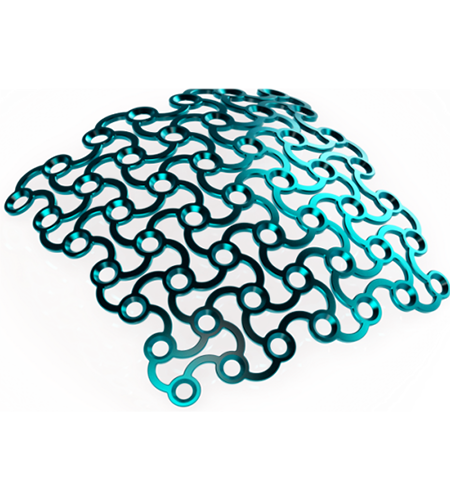

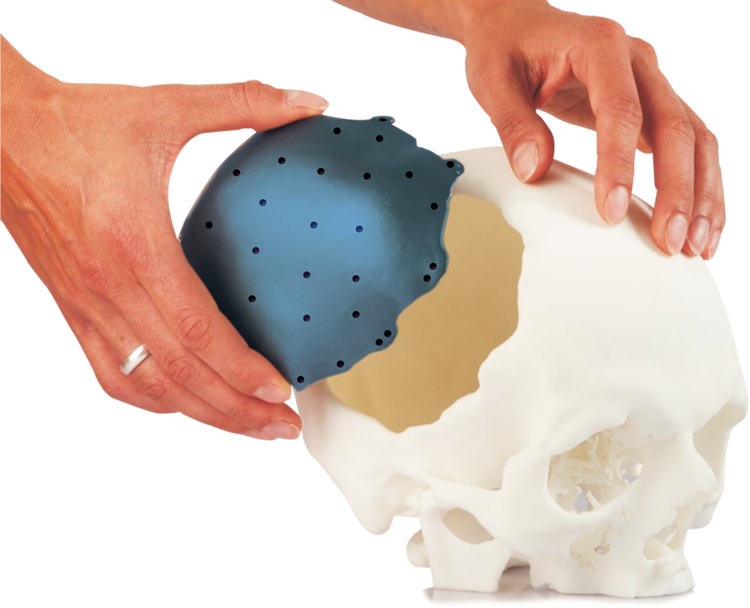

- Custom Made Cranial Implant

- Craniofacial Implants

- Better anatomic fit

- Complex structures possible

- Reduced operating time

- Satisfying aesthetic results

PSI & CRANIAL / MAXILLOFACIAL

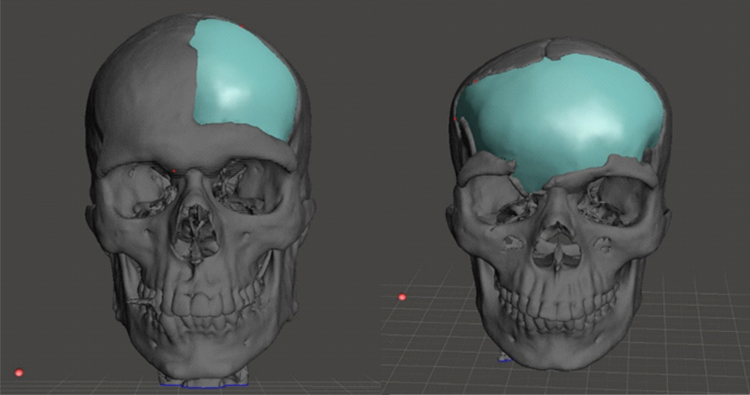

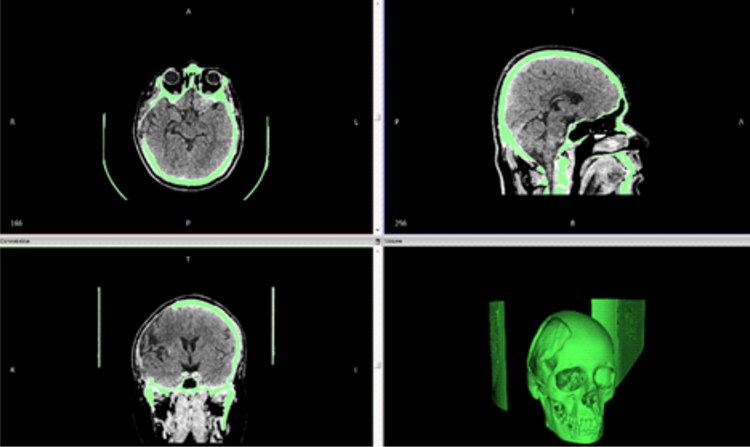

CONSTRUCTION OF A 3D-IMPLANT MODEL

On the basis of the virtual 3D-patient model an implant model is constructed. After consultation between you, the treating physician, and our technical designers, you determine the final implant shape. The consultation can take place either via telephone or via E-mail. If necessary we send you also real 3D- model for the implant planning.

- Main fields of application:

- Neurosurgery

- Casualty surgery

- Tumour surgery

- Maxillofacial Surgery

How long do you need for the production of an implant?

We need approx. 3 work days, but in case of an emergency, we are able to provide it within 48 hrs.

A perfect fit implant as per your patient anatomy

PATIENT SPECIFIC IMPLANTS

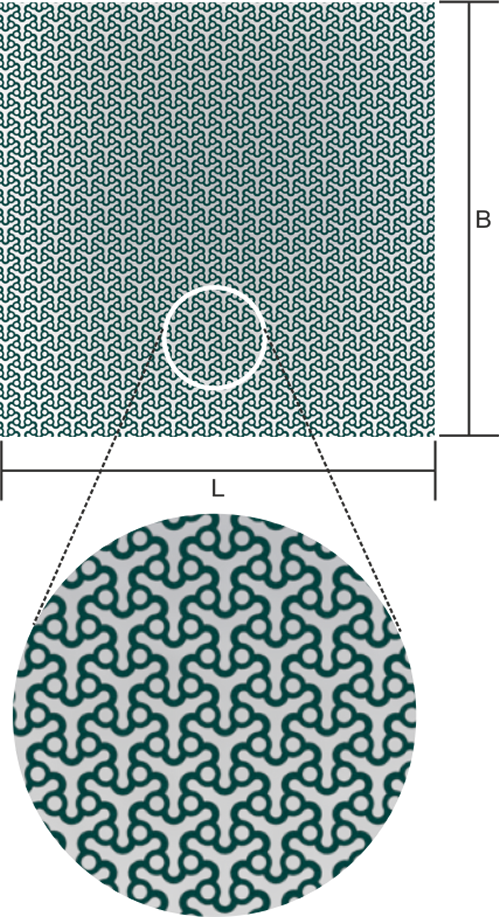

Patient-specific implants are designed and produced according to patient-derived CT data for excellent reconstructive results. Our main products are patient-specific implants for the brain- and face-skull areas. These patient-specific implants can, for example, become a necessity after trauma, tumour surgeries, surgery accesses. This new procedure allows us to create implants that are custom-made for every patient.

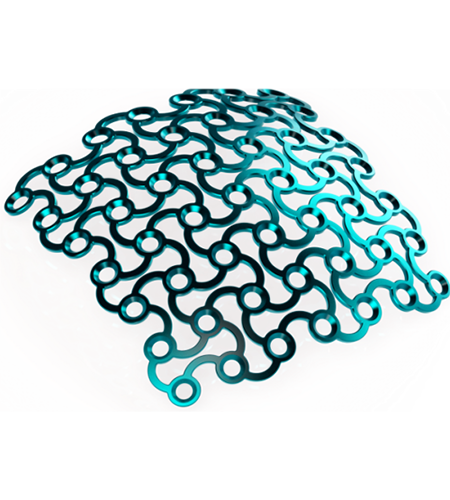

Implant material

- Commercially pure titanium

- Ultra-high strength

- Excellent biocompatibility

- Radiopaque

- Autoclavable – withstands repeated sterilization

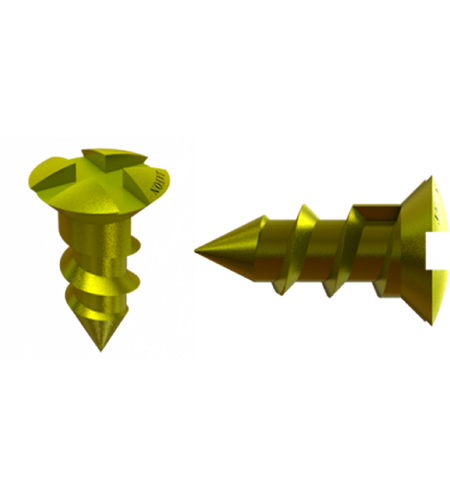

- Requires the use plates and screws are used to attach the patient specific implant to native bone.

PSI process

Data acquisition

First of all, the necessary data of the patient is gathered with the imaging procedure like computer tomography and afterward stored, e.g. in DICOM- format.

Data transfer

The Data can be saved to CD-ROM, DVD USB flash drive can be send to us. Also you are welcomed to send us the data quickly with our mail id : psi@jayon.in

Data preparation

The data of the patient is prepared and converted by us; a virtual 3D-patient model is created.

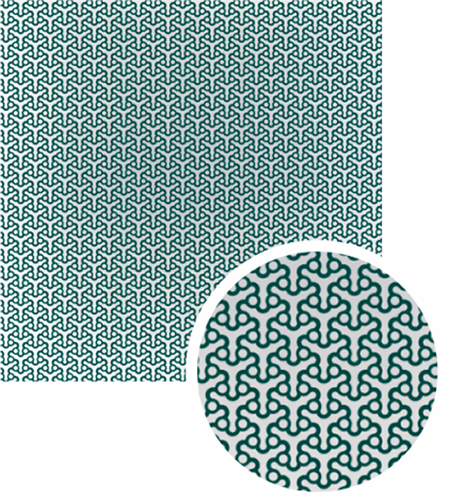

Material selection and manufacturing

The material is selected, according to medical and technical aspects; manufacturing is carried out in our modern fabrication centere.